Selection of stainless steel

The use of most steel pipes is required to maintain the original appearance of the building for a long time. When determining the type of stainless steel to be used, the aesthetic standards required, the corrosiveness of the local atmosphere and the cleaning system to be adopted are taken into account.However, other applications increasingly seek only structural integrity or impermeability. For example, the roofs and side walls of industrial buildings. In these applications, the owner’s construction cost may be more important than aesthetics, and it is acceptable if the surface is not very clean.304 stainless steel is quite effective in dry indoor environment. However, in rural and urban areas to maintain its appearance outdoors, frequent cleaning is required. In heavily polluted industrial areas and coastal areas, surfaces can become very dirty and even rusty.

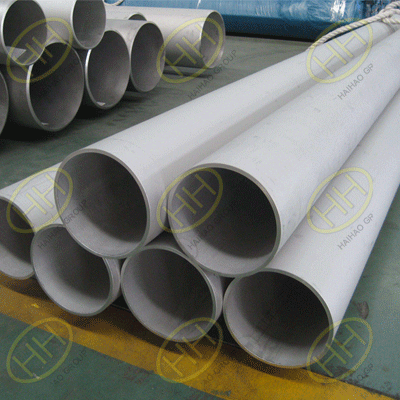

Stainless steel ERW pipe

But to obtain the aesthetic effect in the outdoor environment, it is necessary to use nickel-containing stainless steel. Therefore, 304 stainless steel is widely used for curtain wall, side wall, roof and other construction purposes, but in the severe industrial or oceanic atmosphere, it is better to use 316 stainless steel.The advantages of using stainless steel in structural applications have now been fully recognized. There are several design criteria including 304 and 316 stainless steel. The European code also includes duplex stainless steel 2205 because it combines good atmospheric corrosion resistance with high tensile and elastic strength.

ASTM A182 F347H Pipe Fittings In Haihao Group

In fact, stainless steel is manufactured in all standard metal shapes and sizes, and there are many special shapes. The most commonly used products are made of sheet and strip steel, but special products are also made of medium and thick plates, for example, hot rolled structural sections and extruded structural sections. There are also round, oval, square, rectangular and hexagonal welded or seamless tubes and other forms of products, including profiles, bars, wires and castings.