S22053 vs. 316L Stainless Steel Welded Pipes: Key Differences and Selection Guide

When selecting stainless steel materials for critical projects, engineers often compare S22053 vs. 316L stainless steel welded pipes. Both grades are widely used, yet they show remarkable differences in composition, mechanical strength, and resistance to corrosion. At Ganyeah Group, we provide a clear analysis of the differences between S22053 and 316L stainless steel welded pipes, helping clients choose the most cost-effective and durable solution.

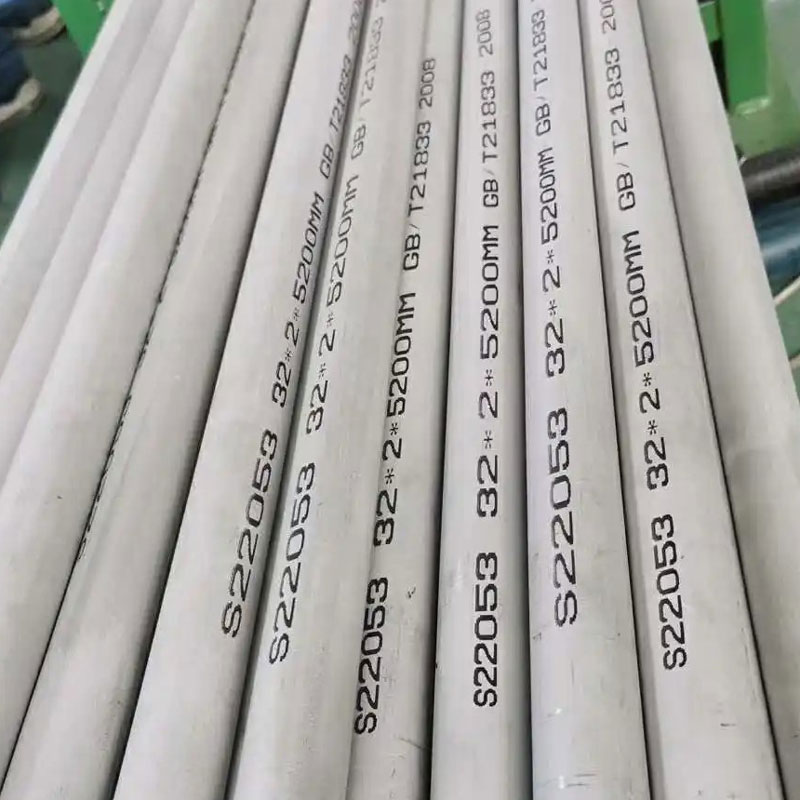

S22053 stainless steel welded pipes used in offshore platforms

1. Material and Composition

- S22053 (022Cr22Ni5Mo3N): A duplex stainless steel with a balanced microstructure of austenite and ferrite. Its alloy design includes 22–23% Cr, 4.5–6.5% Ni, 3.0–3.5% Mo, and 0.14–0.20% N, delivering exceptional resistance to chloride and stress corrosion.

- 316L (06Cr17Ni12Mo2): An austenitic stainless steel containing 16–18% Cr, 10–14% Ni, and 2–3% Mo, widely used for general applications requiring hygiene and moderate corrosion resistance.

2. Mechanical Properties

- Strength: S22053 offers a yield strength ≥450 MPa, more than 2.5 times higher than 316L (≥170 MPa). This allows thinner wall designs (40–50% reduction), reducing weight and cost in structural systems.

- Toughness: S22053 maintains impact toughness ≥40 J at –50 °C, making it reliable for LNG transport and Arctic pipelines. In contrast, 316L becomes brittle under extreme cryogenic conditions.

- Service Life: In high-pressure environments, S22053 can last 2–3 times longer than 316L, lowering long-term replacement and maintenance costs.

3. Corrosion Resistance

- Chloride-rich Environments: With a pitting resistance equivalent number (PREN) ≥35, S22053 performs far better than 316L (PREN ≈26), offering longer life in seawater desalination, offshore pipelines, and oil & gas fields.

- Acid Media: S22053 withstands dilute sulfuric acid and organic acids, while 316L is limited to weaker acids such as low-concentration acetic acid.

- Stress Corrosion Cracking (SCC): Duplex microstructure makes S22053 nearly five times more resistant to SCC than 316L, preventing cracking in humid, high-temperature marine atmospheres.

4. Processing and Cost Considerations

- Fabrication: 316L is easier to cold form and weld using standard TIG welding. In contrast, S22053 requires specialized filler metals (ER2209) and controlled heat input, increasing processing costs by 30–50%.

- Initial Cost: S22053 costs approximately 2.5–3 times more than 316L due to high nickel, molybdenum, and nitrogen content.

- Lifecycle Value: Despite higher upfront investment, S22053 delivers superior durability and lower maintenance, making it more economical for harsh environments.

5. Typical Applications

- S22053 Stainless Steel Welded Pipes: Offshore oil & gas pipelines, seawater desalination plants, chemical reactors, LNG low-temperature circulation systems.

- 316L Stainless Steel Welded Pipes: Food processing, medical equipment, architectural decoration, and light chemical equipment in weakly corrosive environments.

316L stainless steel welded pipes producted by Ganyeah

6. Selection Guide

- For high chloride, high pressure, or low-temperature conditions → Choose S22053.

- For cost-sensitive, moderate environments → Choose 316L.

- For complex cold forming and frequent bending → Choose 316L.

- For long-term reliability with reduced maintenance → Choose S22053.

Why Choose Ganyeah Group?

At Ganyeah Group, we manufacture and supply both S22053 and 316L stainless steel welded pipes, ensuring strict quality control, international certifications, and reliable delivery. By understanding the differences between S22053 and 316L stainless steel welded pipes, our clients can confidently select the right material for their projects.

📩 Contact Ganyeah Group today to get expert guidance and a customized quotation for your stainless steel pipeline solutions.