Advantages and Limitations of S22053 Stainless Steel Welded Pipes

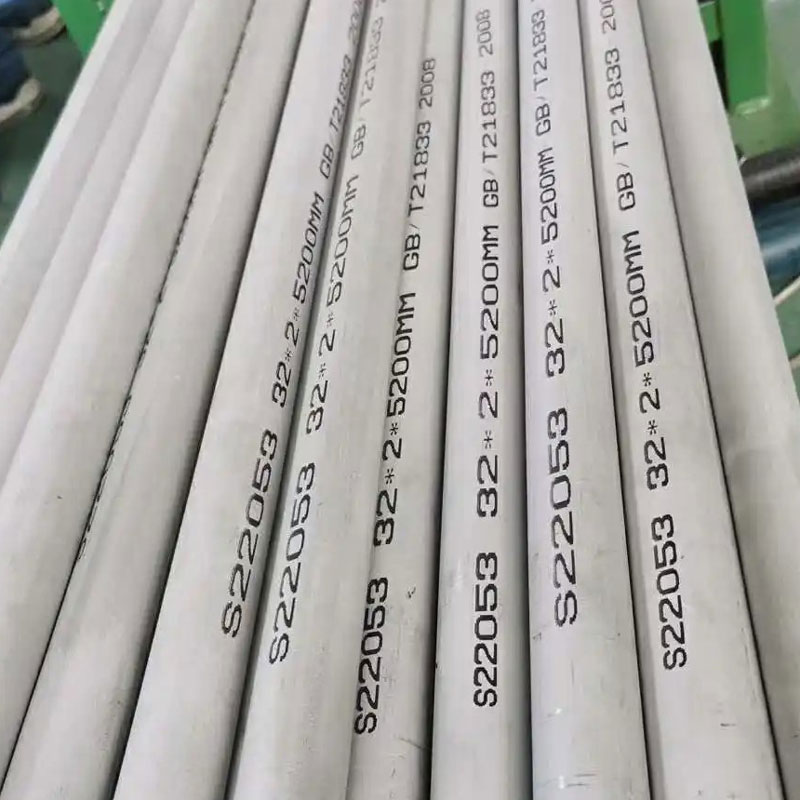

S22053 stainless steel welded pipes (UNS S22053 / 022Cr22Ni5Mo3N) are advanced duplex stainless steels that combine the benefits of austenitic and ferritic structures. With a carefully balanced chemical composition-Cr 22-23%, Ni 4.5-6.5%, Mo 3.0-3.5%, and N 0.14-0.20%-this grade delivers exceptional corrosion resistance, high mechanical strength, and reliability in demanding environments. However, like any material, it also has certain limitations that should be considered when selecting for specific applications.

At Ganyeah Group, we supply S22053 stainless steel welded pipes engineered for durability and efficiency, ensuring clients achieve both technical performance and cost-effectiveness.

S22053 stainless steel welded pipes used in offshore platforms

Key Advantages of S22053 Stainless Steel Welded Pipes

1. Superior Corrosion Resistance

- Chloride resistance: With a PREN ≥35, S22053 significantly outperforms 316L (PREN ≈26), offering excellent protection against pitting and crevice corrosion in seawater and oilfield chloride media. Service life can be 2–3 times longer than 316L.

- Stress corrosion cracking (SCC) resistance: Performs reliably in environments containing H₂S and CO₂, making it ideal for subsea pipelines and sour gas wells.

- Acid resistance: Performs well in weak acid environments such as diluted sulfuric acid and acetic acid, making it suitable for chemical reactors and wastewater systems.

2. High Strength and Lightweight Design

With a yield strength ≥450 MPa (double that of 316L) and tensile strength ≥620 MPa, S22053 pipes allow wall thickness reduction of up to 40-50%. This saves material and transportation costs while ensuring excellent load-bearing capacity-an advantage in offshore platforms.

3. Excellent Low-Temperature Toughness

S22053 maintains impact toughness ≥40 J at -50 °C, making it reliable for LNG storage and transportation as well as pipelines in cold regions, without requiring additional low-temperature steels.

4. Long-Term Economic Benefits

Although the initial purchase price is 1.8-2 times that of 304 stainless steel, its longer service life (2-3 times), reduced maintenance (no need for anti-corrosion coating), and improved reliability deliver lower lifecycle costs, especially in harsh environments.

Limitations of S22053 Stainless Steel Welded Pipes

1. Higher Initial Cost

Due to higher alloy content (Ni, Mo, N), S22053 is more expensive than 304 and carbon steel, making it less suitable for low-risk environments such as freshwater piping.

2. Processing Challenges

- Cold working: With an elongation of about 25% (lower than 304’s 40%), cold bending and stamping may lead to cracking, often requiring repeated annealing.

- Hot working: Limited to 950-1100 °C with rapid cooling to prevent sigma phase formation, restricting its use in complex shapes.

3. Complex Welding Requirements

S22053 requires dedicated filler metals (e.g., ER2209), precise heat input control, and post-weld inspections (UT/RT). Improper welding can alter the ferrite-austenite balance, reducing corrosion resistance or strength. Welding increases fabrication cost by 30-50%.

4. Application Boundaries

Not recommended for extreme conditions such as concentrated hydrochloric acid, hydrofluoric acid, or continuous exposure to seawater above 200 °C. In these cases, alloys like 2507 super duplex or nickel-based alloys are better suited.

Application Scenarios

| Industry / Application | Performance Benefits | Alternatives |

|---|---|---|

| Seawater desalination | Excellent chloride resistance, maintenance-free for 10-15 years | 316L (frequent replacement) |

| High-sulfur oil & gas wells | SCC resistance, pressure tolerance up to 60 MPa | Carbon steel + inhibitors (higher cost) |

| LNG pipelines | High toughness at -50 °C, no embrittlement risk | Low-temperature steels (higher cost) |

| Food processing | Hygienic, easy to clean, good weak acid resistance | 304 (lower chloride resistance) |

| General construction | Cost too high, not economical | 304 or coated carbon steel |

Selection Recommendations

- Recommended use: Offshore platforms, chemical reactors, subsea pipelines, and high-pressure systems where resistance to chlorides, sulfides, and low temperatures is critical.

- Avoid use: Municipal water pipelines, complex cold-formed components, and ultra-high temperature or strong reducing acid environments.

By carefully evaluating performance and cost, S22053 stainless steel welded pipes demonstrate irreplaceable advantages in critical industries but should be applied with precision to maximize value.

S22053 stainless steel welded pipes provide a strong balance of corrosion resistance, mechanical strength, and cost-effectiveness in demanding applications. With proper selection, fabrication, and welding practices, they can outperform traditional grades like 316L and carbon steel in both durability and lifecycle economy.

At Ganyeah Group, we deliver certified S22053 welded pipes tailored to client specifications, ensuring optimal performance in offshore, oil and gas, chemical, and cryogenic applications.

👉 Contact Ganyeah Group today to learn more about our S22053 stainless steel welded pipe solutions and how they can enhance your next project.