S22053 vs. 304 Stainless Steel Welded Pipes: Key Differences and Applications

When selecting stainless steel materials for industrial pipelines, the comparison between S22053 vs. 304 stainless steel welded pipes is critical. Although both are widely used, their differences in microstructure, corrosion resistance, and cost-effectiveness make them suitable for distinct applications. At Ganyeah Group, we help clients understand the differences between S22053 and 304 stainless steel welded pipes to make the right choice for their projects.

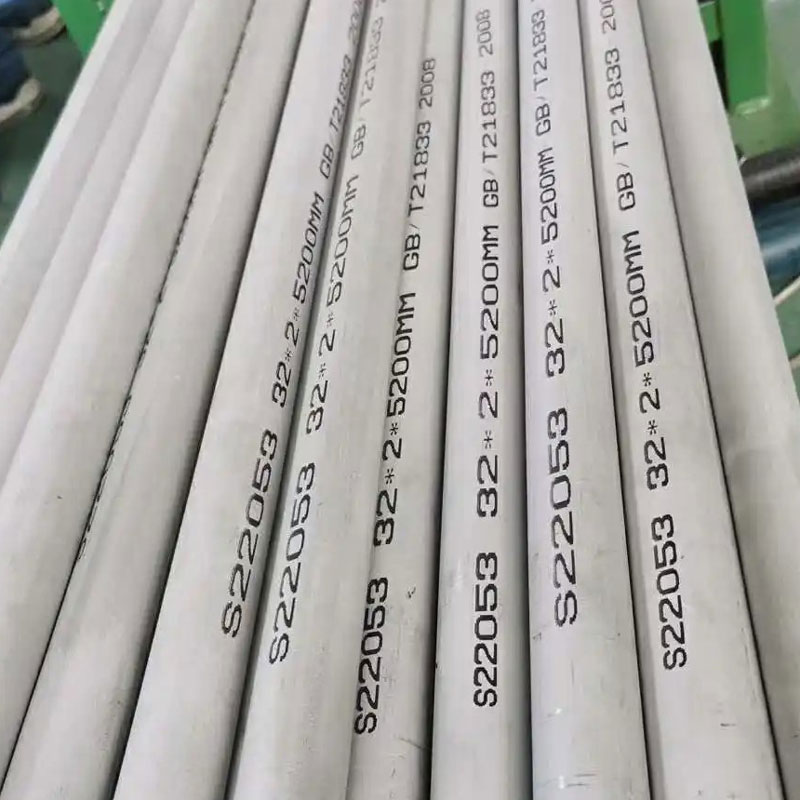

S22053 stainless steel welded pipes used in offshore platforms

1. Material and Composition

- S22053 (022Cr22Ni5Mo3N): A duplex stainless steel with a balanced austenitic-ferritic structure (≈50:50). Alloyed with 22–23% Cr, 4.5–6.5% Ni, 3.0–3.5% Mo, and 0.14–0.20% N, it offers excellent chloride resistance.

- 304 (06Cr19Ni10): Austenitic stainless steel containing 18–20% Cr and 8–10.5% Ni, without Mo or N. Its simpler composition makes it cost-effective and easy to process.

2. Mechanical Properties

- Strength: S22053 provides yield strength ≥450 MPa (twice that of 304 at ≥205 MPa) and tensile strength ≥620 MPa, enabling thinner walls and lighter designs.

- Toughness: S22053 maintains impact toughness at –50 °C, making it suitable for LNG transport and low-temperature pipelines. By contrast, 304 risks embrittlement at ultra-low temperatures (below –196 °C).

3. Corrosion Resistance

- Chloride Environments: With a PREN ≥35, S22053 outperforms 304 (PREN ≈18–20), resisting pitting and crevice corrosion in seawater and chloride-rich oil & gas environments.

- Acid Resistance: S22053 withstands dilute sulfuric acid and organic acids, whereas 304 is limited to weak acids such as acetic acid.

- Stress Corrosion Cracking (SCC): S22053’s duplex structure makes it five times more resistant to SCC than 304, minimizing failure risks in humid or high-temperature operations.

4. Physical Properties

- Thermal Conductivity: S22053 has 40% higher thermal conductivity than 304, improving heat transfer efficiency in industrial equipment.

- Thermal Expansion: S22053’s low expansion coefficient (≈1.0×10⁻⁶/°C) reduces thermal stress when connected to carbon steel, offering an advantage over 304.

5. Fabrication and Cost

- S22053: More difficult to process due to work hardening. Requires special filler wires (ER2209) and strict welding control. Its initial cost is 2.5–3 times higher than 304, but its service life is 2–3 times longer.

- 304: Easy to bend, weld, and form using conventional methods. While cheaper, it requires frequent replacement in harsh environments, increasing lifecycle costs.

ASTM A312 TP304 Stainless Steel Pipes Finished By Ganyeah Holding Group

6. Application Comparison

S22053 stainless steel welded pipes:

- Offshore engineering, subsea pipelines, desalination units

- High-pressure reactors, chemical storage tanks

- LNG transportation and low-temperature environments

304 stainless steel welded pipes:

- Food processing pipelines

- Architectural applications (railings, handrails)

- General-purpose piping in mild environments

7. Selection Guide

- Corrosive Environments with high Cl⁻ or H₂S → S22053

- General weak acid or freshwater pipelines → 304

- High-pressure or load-bearing systems → S22053

- Cost-sensitive, short-term projects → 304

When comparing S22053 vs. 304 stainless steel welded pipes, the choice depends on service life requirements, budget considerations, and exposure to chlorides or pressure.

Why Choose Ganyeah Group

The comparison of S22053 vs. 304 stainless steel welded pipes clearly shows that S22053 offers unmatched performance in harsh and high-pressure conditions, while 304 remains a cost-effective solution for general applications.

At Ganyeah Group, we supply both S22053 and 304 stainless steel welded pipes, manufactured under strict international standards. By understanding the differences between S22053 and 304 stainless steel welded pipes, our clients can select the right material to balance durability, cost, and performance.

📩 Contact us today for tailored stainless steel piping solutions that maximize long-term value.