How to Choose the Right Stainless Steel Heat Exchanger Tubes or Fluid Pipes

When selecting stainless steel heat exchanger tubes or fluid pipes, the decision directly affects system efficiency, safety, and long-term operating costs. Each product serves a different purpose-heat exchanger tubes focus on thermal transfer, while fluid pipes ensure safe and reliable transport of liquids or gases. Understanding these differences allows engineers and buyers to make the best choice for performance and value. At Ganyeah Group, we specialize in providing high-quality stainless steel piping solutions tailored to diverse industry needs.

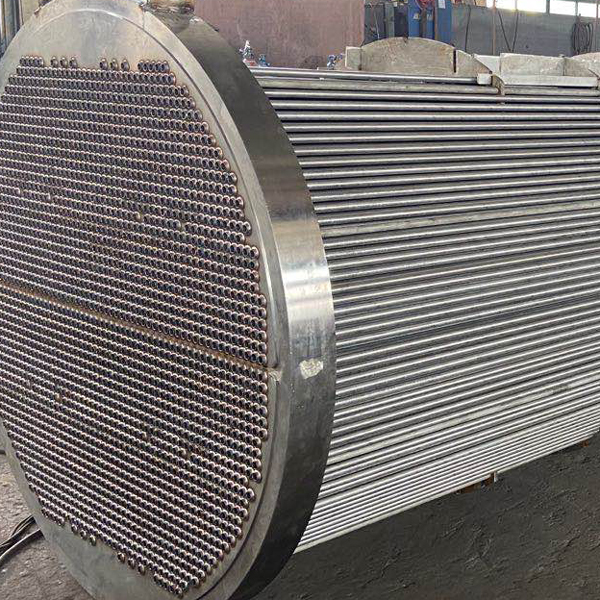

Industrial stainless steel heat exchanger tubes in chemical plant

Identify the Right Function for Your Application

Stainless Steel Heat Exchanger Tubes

These tubes are engineered for condensers, boilers, and cooling systems, where efficient heat transfer is critical. Their thin walls, small diameters, and optional enhanced designs (finned or corrugated) maximize thermal efficiency and minimize scaling, helping reduce energy consumption and extend service intervals.

Stainless Steel Fluid Pipes

Fluid pipes are designed to transport water, oil, gas, or chemicals through industrial piping networks. With smooth inner surfaces and strong pressure resistance, they guarantee safe and consistent delivery. Choosing the right fluid pipe helps reduce pumping costs, avoid leakage, and lower long-term maintenance expenses.

Consider Operating Conditions

- Medium:

- For mild conditions (water, weak acids), 304 stainless steel offers a cost-effective balance.

- For chloride-rich environments (seawater, brine), 316L or 2205 duplex stainless steel ensures superior corrosion resistance and durability.

- For high-temperature service (steam, flue gas), 321 and 310S provide oxidation resistance and stability.

- Temperature & Pressure:

- At high temperatures above 300°C, stainless steel heat exchanger tubes must combine conductivity with creep resistance, while fluid pipes must meet strict ASME and GB/T standards.

- For high-pressure applications, seamless tubes with thicker walls safeguard against stress and extend operating life.

- Flow Conditions:

- Heat exchanger tubes typically use small diameters (φ19mm, φ25mm) for dense configurations and better heat exchange.

- Fluid pipes are selected by flow rate, ensuring efficient velocity while minimizing energy costs.

stainless steel pipes supply by Ganyeah Group

Select the Best Stainless Steel Grade

- 304: General-purpose, cost-efficient.

- 316L: Chloride resistance for chemical and marine use.

- 2205 Duplex: High strength and fatigue resistance for harsh conditions.

- 321 / 310S: Heat stability under elevated temperatures.

- Nickel Alloys: Extreme durability for severe industrial applications.

At Ganyeah Group, we stock and supply a full range of stainless steel grades, ensuring customers receive materials that match both technical requirements and budget.

Design and Standards Matter

- Heat Exchanger Tubes: Thin-walled designs (≤1mm), 3–12m in length, with optional enhancements like corrugated or finned tubes to improve turbulence and reduce fouling.

- Fluid Pipes: Smooth bore or polished sanitary pipes with options for welded, clamped, or threaded connections, ensuring both hygiene and durability.

All Ganyeah Group products comply with international standards, including ASTM A213, ASTM A312, GB/T 24593, and EN 10217-7, and undergo rigorous testing such as hydrostatic, eddy current, and corrosion resistance inspections.

Practical Considerations

- Cost & Delivery: Standard stainless steel fluid pipes are often available immediately, while specialized heat exchanger tubes may require customization. Choosing the right balance reduces project delays and unnecessary expenses.

- Fabrication Needs: Heat exchanger tubes must withstand expansion or welding, while fluid pipes should allow easy bending and forming.

- Industry-Specific Requirements: Sanitary-grade pipes (316L, polished Ra ≤0.8μm) are essential for food and pharmaceutical industries, while nuclear and aerospace sectors demand 100% radiographic testing.

By working with Ganyeah Group, customers gain access to technical expertise, fast delivery, and tailored solutions that reduce downtime and maximize system efficiency.

The choice between stainless steel heat exchanger tubes and fluid pipes depends on core function, environment, and performance goals. Heat exchanger tubes excel in thermal transfer, while fluid pipes ensure safe, long-lasting transport of fluids and gases. Selecting the right option improves efficiency, reduces operational costs, and extends service life.

At Ganyeah Group, we help customers worldwide make the right selection by offering high-quality stainless steel products that deliver proven reliability and value. Contact us today to discuss your project and secure the best stainless steel solution for your industry.

Related Articles:

- Applications of Stainless Steel Heat Exchanger Tubes

- Advantages of Stainless Steel Heat Exchanger Tubes Compared to Other Materials

- Stainless Steel Heat Exchanger Tubes vs. Fluid Pipes: Key Differences and Industrial Applications

- How to Improve the Heat Transfer Efficiency of Stainless Steel Heat Exchanger Tubes

- Factors Affecting the Fouling Thermal Resistance of Stainless Steel Heat Exchanger Tubes