Stainless Steel Surface Treatment Technologies: A Technical Comparison of EP and BA Processes

In high-end stainless steel tubing manufacturing, stainless steel surface treatment technologies determine the final performance and application value of the product. Among these, EP stainless steel tubes (Electropolished) and BA stainless steel tubes (Bright Annealed) stand out as the most widely used processes. Each method delivers unique benefits, making it essential for engineers and project managers to select the right option based on system requirements, cleanliness, and cost efficiency.

Electropolished stainless steel tubes in Ganyeah Group

Deep Technical Insights into EP and BA Processes

Electropolishing (EP)

Electropolishing (EP) is an advanced electrochemical finishing method. By immersing stainless steel tubes as the anode in a controlled electrolyte and applying current, microscopic peaks on the surface are selectively dissolved. This process removes 20–40 μm of the metal layer (ASTM B912) and creates an exceptionally smooth and passive surface.

- Surface roughness: Achieves Ra 0.1–0.2 μm, far smoother than BA tubing.

- Corrosion resistance: Dense passive film resists chloride attack, doubling service life compared with BA tubes (ASTM B117 salt spray test).

- Purity assurance: Metal ion release controlled at ≤0.05 ppb (SEMI F57 standard), critical for ultra-clean applications.

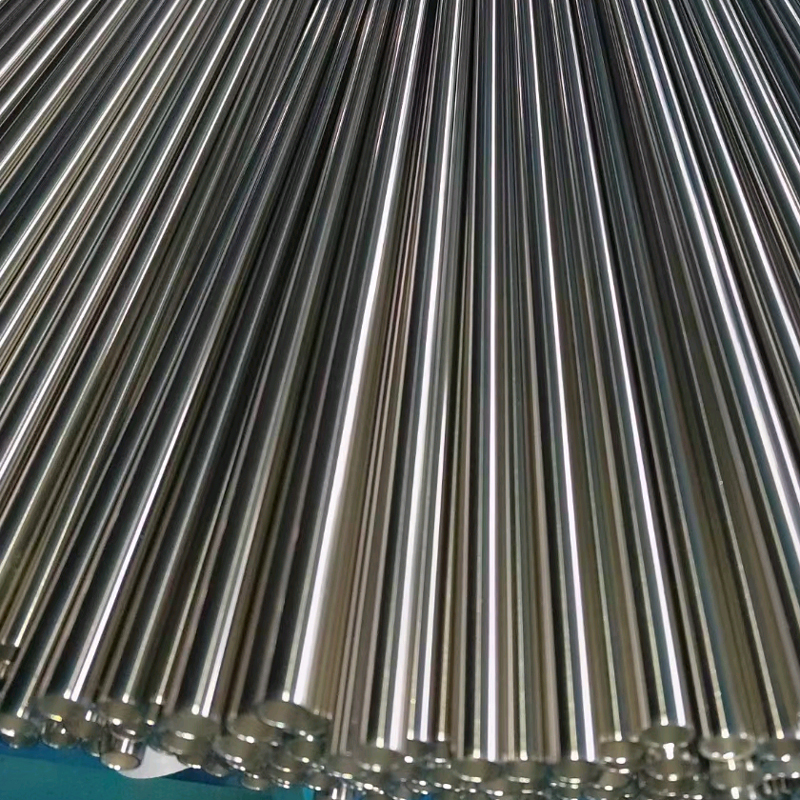

Bright annealed stainless steel tubes are ready for shipment

Bright Annealing (BA)

Bright Annealing (BA) is a controlled heat treatment carried out under a vacuum or protective hydrogen atmosphere at 1050–1150°C (ASTM A270). By precisely regulating cooling rates, the process eliminates residual stress while producing a clean, reflective surface without oxidation scale.

- Surface roughness: Generally Ra 0.3–0.5 μm, smoother than untreated tubes but not as refined as EP.

- Mechanical stability: Maintains excellent strength, formability, and weldability.

- Cost-effectiveness: More economical than EP, making it suitable for general industrial use.

Performance Comparison: EP vs BA

| Property | EP Stainless Steel Tube | BA Stainless Steel Tube |

|---|---|---|

| Surface Roughness (Ra, μm) | 0.1–0.2 (Ultra-smooth) | 0.3–0.5 (Smooth) |

| Corrosion Resistance | Excellent (up to 1000h salt spray) | Good (approx. 500h) |

| Metal Ion Release (ppb) | ≤0.05 | ~0.1 |

| Microbial Growth Resistance | Very high | Moderate |

| Mechanical Strength | Moderate | High |

| Typical Cost Level | Higher | Lower |

Application Scenarios

EP Stainless Steel Tubes

- Semiconductor Manufacturing

In wafer fabs operating at 7nm and below, more than 90% of high-purity gas delivery systems use electropolished stainless steel tubing. SEMI F19 standards require Ra ≤0.5 μm to prevent particle contamination and wafer defects. - Biopharmaceutical Industry

In WFI (Water for Injection) and pure steam systems, EP tubing complies with FDA CFR 211.65 and ASME BPE, offering superior cleanability and reducing microbial adhesion by 30% or more. - Ultra-High Vacuum (UHV) Systems

For particle accelerators and aerospace equipment, EP stainless steel pipes combined with 316L VIM/VAR metallurgy provide unmatched purity and corrosion resistance.

BA Stainless Steel Tubes

- Food & Beverage Processing

BA stainless steel pipes dominate dairy and beverage systems, balancing 3-A sanitary standard compliance with cost efficiency. - General Electronics Manufacturing

For LCD panel and mid-level electronics production, bright annealed stainless steel tubing offers sufficient cleanliness with better forming performance. - Chemical Industry

In transporting neutral or mildly corrosive chemicals, BA tubes provide adequate resistance at 30% lower initial investment compared to EP tubes.

Ganyeah’s Technical Expertise

At Ganyeah Group, we bring decades of expertise in stainless steel surface treatment technologies, offering customers tailored solutions across industries.

- Process Selection Support: Our technical team evaluates application requirements and recommends whether EP or BA stainless steel tubes best balance performance and cost.

- System Integration Services: Full compliance with ASME BPE, including helium leak testing and piping integrity validation.

- On-Site Welding and Installation: Using imported orbital welding systems, our certified engineers ensure weld quality that meets GMP requirements, achieving a 99% first-pass acceptance rate.

Choosing between EP stainless steel tubes and BA stainless steel tubes depends on the balance between performance requirements and cost considerations. For semiconductor, pharmaceutical, and ultra-clean applications, electropolished stainless steel tubing offers unmatched advantages in purity and corrosion resistance. For food, beverage, and general chemical industries, bright annealed stainless steel pipes remain a reliable, cost-effective solution.

With Ganyeah’s expertise in EP and BA stainless steel surface treatment technologies, customers can be confident in achieving the right technical balance for every project. Contact our team today to discuss customized solutions tailored to your industry needs.