Electric resistance welded (ERW) pipe is manufactured by cold-forming a sheet of steel into a cylindrical shape. Current is then passed between the two edges of the steel to heat the steel to a point at which the edges are forced together to form a bond without the use of welding filler material. Initially this manufacturing process used low frequency A.C. current to heat the edges. This low frequency process was used from the 1920’s until 1970. In 1970, the low frequency process was superseded by a high frequency ERW process which produced a higher quality weld. Over time, the welds of low frequency ERW pipe was found to be susceptible to selective seam corrosion, hook cracks, and inadequate bonding of the seams, so low frequency ERW is no longer used to manufacture pipe. The high frequency process is still being used to manufacture pipe for use in new pipeline construction.

Electric resistance welding can be divided into two kinds:resistance welding and induction welding.ERW pipe is cold formed into a cylindrical shape rather than hot formed. An electric current rather than a flame is used to heat the edges of the strip for the fusion weld. Revolving copper discs serve as electrodes and raise the temperature to about 2600°F for effective welding. Different from longitudinally Submerged Arc Welding,Usually ERW uses AC with frequency from 100 to 800 kHz, or 100.000 to 800.000 cycles per second. This process is characterized by two effects: skin effect, or concentration of high-frequency current on the surface, and proximity effect when a high-frequency concentrates on the two adjacent parallel inner edges in the welded wedge, before the welding point. These effects allow a welding process to take place with the least amount of heat released, and because of that the structure of the basic material changes in a relative small zone around the central – ferit line of welds. Scavenging melted material from inner and outer side of the weld is removed by scraping devices.

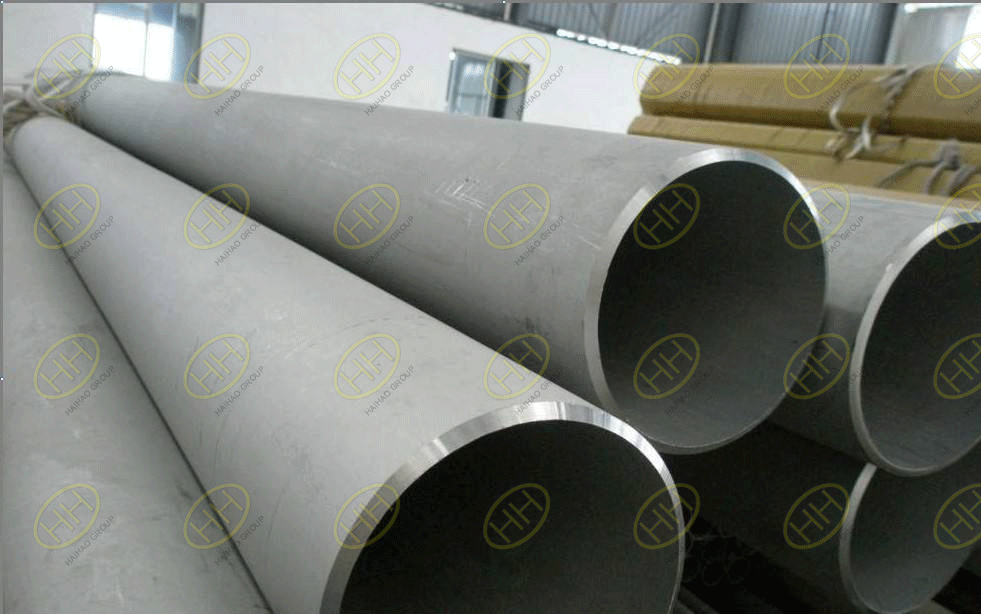

Sizes

ERW Steel Pipes: 1/2″ to 20″ .

Specifications & Grades

ASTM A312 TP304/304L, TP316/316L, TP321, TP310, Duplex SS