Material Differences in Sanitary Stainless Steel Pipes and Their Performance

In hygienic industries such as food processing, pharmaceuticals, and beverage production, sanitary stainless steel pipes are essential for ensuring cleanliness, corrosion resistance, and long service life. The performance of these pipes largely depends on their material composition—particularly the levels of chromium, nickel, and molybdenum.

At Ganyeah Group, we manufacture and supply a full range of sanitary stainless steel pipes, including 304, 316L, 317L, and 2205 duplex stainless steel, designed to meet different hygiene and corrosion resistance demands. Understanding the key material differences helps customers make the right selection for their process environment.

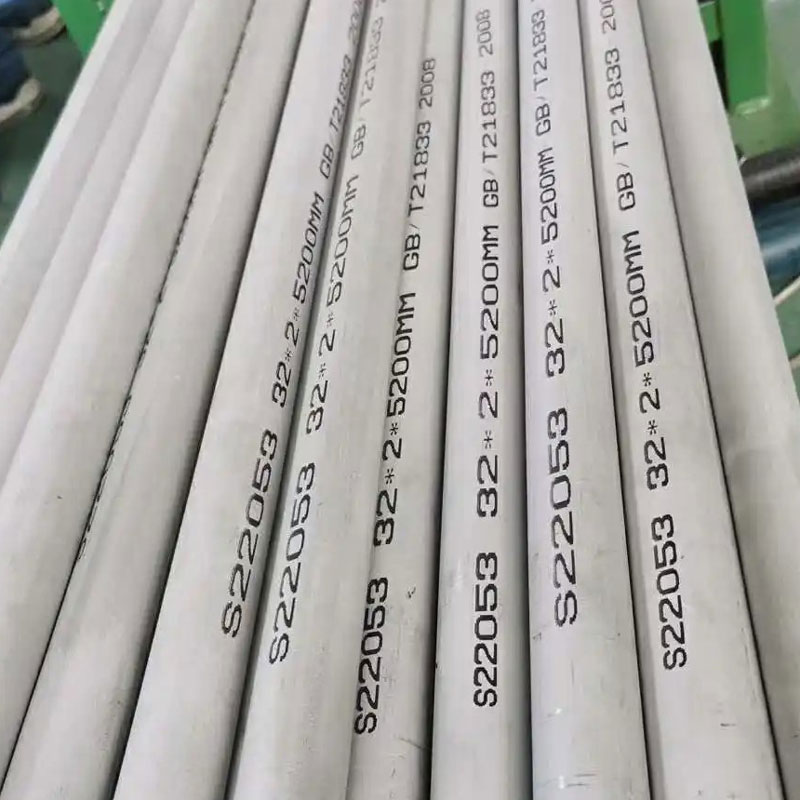

S22053 stainless steel welded pipes used in offshore platforms

1. 304 Stainless Steel Pipe – The Standard Sanitary Choice

Composition: 18% chromium, 8% nickel, no molybdenum.

Performance:

- Corrosion resistance: Suitable for mild environments such as dairy, juice, or general water systems. It resists weak acids and alkalis but is not ideal for chloride-rich or highly corrosive media like saltwater.

- Mechanical strength: Moderate, with tensile strength around 515 MPa, suitable for low-pressure, room-temperature food processing.

- Hygienic surface: Excellent polishability, compliant with FDA and 3-A sanitary standards, and the most cost-effective option for general food-grade pipelines.

2. 316L Stainless Steel Pipe – Enhanced Corrosion Resistance

Composition: 16–18% chromium, 10–14% nickel, 2–3% molybdenum, and ≤0.03% carbon (“L” = low carbon).

Performance:

- Corrosion resistance: The addition of molybdenum provides strong resistance to chloride-induced corrosion, making it suitable for marine food processing, pharmaceutical production, and salt-rich environments.

- Mechanical properties: Similar to 304 but with improved resistance to intergranular corrosion after welding.

- Limitations: Not resistant to strong acids (e.g., concentrated nitric acid) or extreme heat above 800 °C. The cost is typically 30–50% higher than 304.

3. 317L Stainless Steel Pipe – For Highly Corrosive Environments

Composition: Higher molybdenum (3–4%) and nickel than 316L, carbon ≤0.03%.

Performance:

- Corrosion resistance: Excellent protection against high chloride and acidic media, ideal for chemical food additive manufacturing, desalination plants, and cleaning agents exposure.

- Mechanical strength: Stable performance between −196 °C and 450 °C with higher tensile strength than 316L.

- Limitations: High cost (20–30% higher than 316L), typically used only in environments with severe corrosion risk.

4. 2205 Duplex Stainless Steel Pipe – Strength and Stress Corrosion Resistance

Composition: 22% chromium, 5% nickel, 3% molybdenum; microstructure combines austenite and ferrite phases.

Performance:

- Mechanical strength: Outstanding—tensile strength above 800 MPa, 1.5 times that of 304/316L, making it suitable for high-pressure food sterilization systems and industrial water treatment.

- Corrosion resistance: Comparable to 316L with superior stress corrosion cracking resistance, ensuring long service life under both pressure and chemical exposure.

- Limitations: Requires specialized polishing and welding techniques; low-temperature toughness is reduced (not ideal below −50 °C).

5. Key Performance Comparison Table

| Material | Corrosion Resistance | Tensile Strength (MPa) | Temperature Range (°C) | Typical Applications | Cost Level |

|---|---|---|---|---|---|

| 304 | Mild acid, water media | ≈515 | −196 – 870 | Beverage, dairy, water systems | Low |

| 316L | Chloride, medium corrosion | ≈510 | −196 – 870 | Seafood, pharma, infant food | Medium |

| 317L | High chloride, harsh chemicals | ≈520 | −196 – 450 | Chemical additives, brine | High |

| 2205 Duplex | Chloride + stress corrosion | ≈800 | −50 – 300 | High-pressure sterilization, water treatment | Medium |

6. Selection Guidelines

- Corrosion environment first: For chloride-rich or corrosive media, 316L or higher grades are preferred. For clean water or mild acids, 304 offers the best value.

- Pressure and temperature next: 2205 duplex performs best under high pressure (>1.6 MPa), while 304/316L are better for extremely low temperatures (<−50 °C).

- Cost balance: 316L represents the best balance between corrosion resistance, mechanical strength, and cost for most hygienic applications.

Why Choose Ganyeah Group

With decades of manufacturing expertise, Ganyeah Group provides sanitary stainless steel pipes and fittings that comply with 3-A, ASTM, and ISO standards. Our precision welding, polishing, and testing processes ensure smooth internal surfaces, excellent corrosion resistance, and reliability across food, pharmaceutical, and bioprocessing systems.

Whether you require 304, 316L, 317L, or 2205 sanitary stainless steel pipes, Ganyeah Group delivers solutions that align with your hygiene, safety, and cost objectives.