Brushed vs. Mirror Finish Stainless Steel Pipe: Process, Benefits & How to Choose

When selecting stainless steel piping for your project, the brushed vs. mirror finish stainless steel pipe debate is one of the most important considerations. Both finishes are achieved through mechanical polishing but deliver vastly different results in terms of appearance, performance, and application. Whether you need the soft matte elegance of a brushed stainless steel pipe or the flawless reflectivity of a mirror finish stainless steel pipe, understanding their differences will help you make the right choice for your industry and design needs.

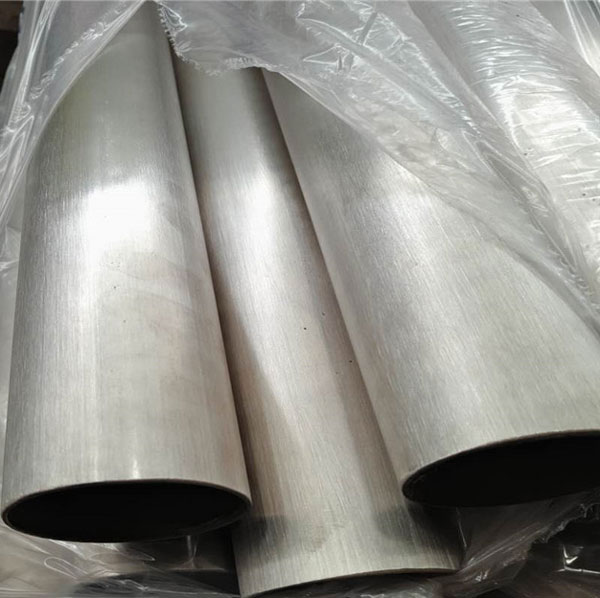

Brushed stainless steel pipes are ready for shipment

The Process for Brushed (Satin) Finish

A brushed finish, also known as a satin finish, gives stainless steel a soft, matte appearance with a subtle grain or texture. The process is designed to create a uniform, non-reflective surface that can effectively hide minor scratches and fingerprints.

1. Initial Grinding: The process begins by grinding the pipe’s surface with progressively finer abrasive belts or wheels. This removes weld seams and major imperfections. The grit is typically coarser at the start, around 80-120 grit, to quickly level the surface.

2.Creating the Grain: To achieve the signature brushed look, the pipe is then polished using a series of fine-grit belts, usually in the range of 180-320 grit. The key is to apply the abrasive in a single, consistent direction. This creates the fine, directional lines that define the finish.

3.Final Cleaning: After polishing, the pipe is thoroughly cleaned to remove any residual particles and oils, resulting in a smooth, elegant, and non-reflective surface. This finish is often referred to as a #4 finish in industry standards.

Mirror finish stainless steel tubing for architectural projects

The Process for Mirror Finish

A mirror finish, also known as a #8 finish, is the highest grade of polish available for stainless steel. It is an intricate, multi-stage process that results in a surface with a mirror-like reflection, free of any visible grain.

1.Preparation and Grinding: Similar to the brushed finish, the process starts with grinding to remove imperfections. However, for a mirror finish, this stage is much more extensive. Multiple grinding steps are performed with a wide range of abrasive grits, from coarse (80 grit) to very fine (as high as 400 grit or more), to systematically eliminate all surface flaws, scratches, and grind lines from the previous step.

2.Buffing: This is the most crucial and time-consuming stage. The pipe is polished using a high-speed buffing wheel made of a soft material like cotton or felt. Specialized polishing compounds, often a paste-like substance containing fine abrasive particles, are applied to the wheel. The buffing wheel polishes the surface to a flawless, reflective sheen, eliminating the fine lines left by the grinding stage.

3.Final Super-Polishing: For the highest quality finish, a final super-polishing stage may be used with an even softer buffing wheel and a non-abrasive compound to achieve the ultimate level of clarity and reflectivity. The resulting surface is completely smooth and non-directional, capable of producing a perfect reflection.

Comparison Table: Brushed vs. Mirror Finish Stainless Steel Pipe

| Feature | #4 Brushed Finish | #8 Mirror Finish |

|---|---|---|

| Appearance | Matte, directional grain | Highly reflective, smooth |

| Maintenance | Hides fingerprints and scratches | Requires regular cleaning |

| Applications | Architecture, furniture, public facilities | Decorative, marine, food & pharmaceutical |

| Durability | High resistance to wear | High resistance to corrosion & staining |

| Cost | Lower polishing cost | Higher polishing cost |

| Hygiene Level | Good | Excellent |

How to Choose the Right Finish

- For heavy-use areas → Choose brushed finish for its ability to hide wear and tear.

- For luxury or decorative projects → Choose mirror finish for its unmatched aesthetic appeal.

- For hygiene-sensitive environments → Both finishes perform well, but mirror finish offers the smoothest surface for easy cleaning.

💡 Tip: We can provide custom polishing services to meet your exact project needs—whether you require satin elegance or mirror brilliance.

Ready to enhance your project with the perfect stainless steel pipe finish?

📞 Contact Ganyeah Group today for expert guidance, competitive pricing, and precision-crafted stainless steel pipes tailored to your requirements.