Austenitic vs. Martensitic Stainless Steel: Which One Fits Your Project Needs?

Austenitic vs. Martensitic Stainless Steel is a common comparison engineers face when selecting the right material for demanding environments. These two stainless steel families differ significantly in chemical composition, mechanical properties, and performance under corrosion or heat. Understanding the difference between austenitic and martensitic stainless steel helps ensure durability, cost-effectiveness, and safe operation in industrial piping, structural components, and precision-machined parts.

At Ganyeah Group, we specialize in providing comprehensive stainless steel solutions. Our expertise helps clients navigate the complexities of material selection, ensuring they choose the perfect alloy for their precise application needs.

Austenitic stainless steel pipe with polished finish for chemical processing

What is austenitic stainless steel?

Austenitic stainless steels are the most commonly used type, representing over 70% of global stainless steel consumption. These alloys are primarily composed of chromium (16–26%) and nickel (6–22%), with additions like molybdenum and nitrogen to improve corrosion resistance and strength. Their internal structure is face-centered cubic (FCC), giving them excellent ductility and toughness.

Key Features:

- Exceptional Corrosion Resistance: Thanks to high chromium content and optional molybdenum, these steels resist a wide range of corrosive agents, including chlorides and acidic environments.

- Excellent Formability and Weldability: The FCC structure gives them excellent ductility, making them highly formable and easy to weld. They can be deep-drawn, bent, and fabricated into complex shapes.

- Non-Magnetic in Annealed Condition: While generally non-magnetic, cold working can introduce slight magnetism.

- Not Heat Treatable: Mechanical strength can be increased only through cold working.

- Good Low-Temperature Performance: Retains toughness even at cryogenic temperatures.

Common Grades:

- 304/304L: The most common grade, containing 18% chromium and 8% nickel, hence its other name, 18-8 stainless steel. It has good corrosion resistance, formability, and weldability, and is often used in applications requiring general corrosion resistance, such as in the food processing, chemical, and architectural industries.

- 316/316L: This austenitic stainless steel contains 16% to 18% chromium, 10% to 14% nickel, and 2% to 3% molybdenum. It has better corrosion resistance than 304/304L, especially in chloride environments, and is often used in applications requiring high corrosion resistance, such as in marine, medical, and chemical industries.

- 321/347: These austenitic stainless steels contain 17% to 19% chromium, 9% to 13% nickel, and 0.3% to 0.7% titanium (321) or niobium (347). They have good corrosion resistance and high-temperature strength, making them suitable for applications requiring high-temperature resistance, such as in exhaust systems and jet engines.

- 201: This type of austenitic stainless steel contains 16% to 18% chromium and 3.5% to 5.5% nickel. It has lower corrosion resistance than 304, but is more affordable and has good formability and weldability. It is often used in applications requiring low to moderate corrosion resistance, such as in automotive trim and kitchenware.

Martensitic stainless steel pipes in Ganyeah workshop

What is martensitic stainless steel?

Martensitic stainless steels are built for hardness, strength, and wear resistance. These alloys typically contain 11.5–18% chromium and higher carbon content (0.1–1.2%). Unlike austenitic steels, martensitic grades can be hardened through heat treatment, giving them an edge in applications where durability and sharpness are essential.

Key Features:

- High Strength and Hardness: Can be quenched and tempered for superior mechanical properties.

- Magnetic: Fully magnetic due to their martensitic structure.

- Moderate Corrosion Resistance: Adequate for less aggressive environments, their corrosion resistance is generally lower than that of austenitic stainless steels.

- Limited Ductility and Weldability: Welding requires careful handling, including pre-heating and post-weld tempering.

- Potential Brittleness: Without proper tempering, these steels can become brittle after hardening.

Common Grades:

- 410: This type of martensitic stainless steel contains 11.5% to 13.5% chromium and has a moderate level of corrosion resistance. It is often used in applications requiring high strength, hardness, and wear resistance, such as in cutlery, pumps, and valves.

- 420: This type of martensitic stainless steel contains 12% to 14% chromium and 0.15% to 0.40% carbon. It has higher corrosion resistance than 410 and is often used in applications requiring high strength, hardness, and wear resistance, such as in surgical instruments, dental equipment, and turbine blades.

- 440C: This martensitic stainless steel contains 16% to 18% chromium and 0.75% to 1.20% carbon. It has the highest level of hardness and wear resistance among martensitic stainless steels, making it suitable for manufacturing high-performance cutting tools, bearings, and valves.

- 431: This type of martensitic stainless steel contains 15% to 17% chromium, 1.25% to 2.50% nickel, and 0.12% to 0.22% carbon. It has good corrosion resistance and high strength, making it suitable for pumps, valves, and marine applications.

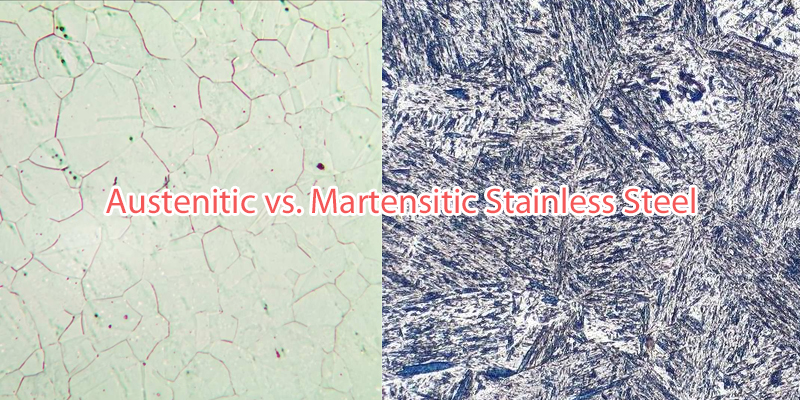

Austenitic vs. Martensitic Stainless Steel Microstructure Diagrams

Choosing Between Austenitic and Martensitic Stainless Steel

When selecting the right stainless steel, consider what your application demands most: corrosion resistance, formability, strength, or hardness.

| Requirement | Recommended Type |

|---|---|

| High corrosion resistance | Austenitic |

| Excellent weldability & formability | Austenitic |

| Non-magnetic properties | Austenitic (annealed) |

| Cryogenic toughness | Austenitic |

| High hardness or wear resistance | Martensitic |

| Heat treatable strength | Martensitic |

| Cost-effective hardness | Martensitic |

Ganyeah Group: Your Expert Partner in Stainless Steel Solutions

Selecting the ideal stainless steel type is a foundational step for any successful project. At Ganyeah Group, with our extensive knowledge and comprehensive inventory of stainless steel pipes and other products across all major families-including both austenitic and martensitic grades—we are here to support you.

We provide:

- Expert Consultation: Our technical specialists can guide you through the selection process, matching the perfect stainless steel grade to your specific application, considering both performance and cost-effectiveness.

- Certified Quality: All our products adhere to strict international standards, ensuring reliability and traceability.

- Diverse Product Range: From 304L and 316L austenitic pipes to specialized martensitic components, we offer solutions for every need.

Need help choosing the right stainless steel alloy? Talk to our experts today – fast quotes, expert support, and reliable delivery from Ganyeah Group.