410 vs 410S vs 430 Stainless Steel: How to Choose the Right Chromium Stainless Steel

Within the stainless steel family, austenitic grades such as 304 and 316 are widely recognized for their excellent corrosion resistance. However, 410, 410S and 430 stainless steel, classified as chromium stainless steels (martensitic and ferritic types), play an equally important role in home appliances, mechanical manufacturing, and kitchenware.

Thanks to their lower cost, distinct mechanical properties, and specific processing advantages, these chromium-based stainless steels offer practical solutions where full austenitic performance is not required. Although they belong to the same “chromium steel” category, differences in carbon and chromium content result in clearly different behaviors and application priorities.

This article explains the core differences, performance logic, and selection strategy for 410, 410S, and 430 stainless steel, helping engineers and buyers choose the right material with confidence.

1. Basic Classification: Martensitic vs Ferritic Stainless Steel

Understanding the microstructure is key to understanding performance.

410 Stainless Steel – Martensitic Grade

- Chromium: 11.5–13.5%

- Carbon: ≤0.15%

- Key feature: Can be hardened by heat treatment

410 stainless steel behaves similarly to quenched carbon steel, offering high strength and wear resistance while retaining basic corrosion resistance.

410S Stainless Steel – Low-Carbon Martensitic Grade

- Chromium: 11.5–13.5%

- Carbon: ≤0.08%

- Optimized for better weldability and corrosion stability

410S is a modified version of 410, designed to reduce intergranular corrosion and cracking during welding.

430 Stainless Steel – Ferritic Grade

- Chromium: 16–18%

- Carbon: ≤0.12%

- Cannot be heat treated for strengthening

430 stainless steel is valued for its atmospheric corrosion resistance, formability, and decorative appearance, making it a cost-effective alternative to austenitic grades.

In short:

- 410 = high strength

- 410S = improved corrosion resistance and weldability

- 430 = economical and decorative

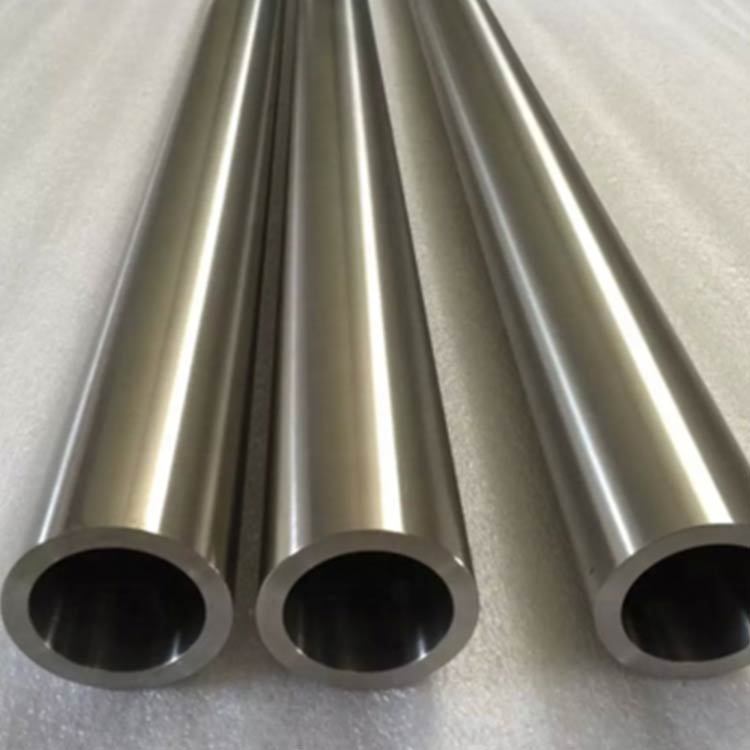

410 stainless steel pipes

2. Selection Guide: Choosing the Right Grade for Your Application

Material selection should balance strength, corrosion environment, fabrication method, and cost.

When to Choose 410 Stainless Steel

Best for:

- Mechanical shafts and wear parts

- Tools, blades, fasteners

- Non-welded structural components

Key advantage: High hardness and strength after heat treatment

Limitation: Poor corrosion resistance in humid or aggressive environments

When to Choose 410S Stainless Steel

Best for:

- Welded stainless steel pipes

- Heat exchangers

- Light-duty food processing equipment

Key advantage: Better weldability and reduced corrosion risk

Limitation: Still unsuitable for strong acids or marine exposure

When to Choose 430 Stainless Steel

Best for:

- Home appliance panels

- Kitchen and bathroom fittings (non-food contact)

- Architectural decoration

Key advantage: Low cost, excellent formability, attractive surface finish

Limitation: Not suitable for acidic or salt-rich environments

When None of These Grades Are Suitable

- Seawater or strong acids: Choose 316 or duplex stainless steel

- Ultra-high strength: Consider precipitation-hardening stainless steel

- Medical or baby food contact: Use 304L or 316L

3. Material Breakdown: Composition, Properties, and Applications

410 Stainless Steel – Strength-Oriented Martensitic Grade

Mechanical Properties:

- Tensile strength up to 700–900 MPa after heat treatment

- High hardness and wear resistance

- Moderate ductility

Corrosion Resistance:

- Suitable for dry or mildly corrosive environments

- Prone to rust in humid or acidic conditions

Typical Applications:

- Pump shafts and valve components

- Turbine blades

- Cutting tools and industrial fasteners

410S Stainless Steel – Improved Corrosion Stability

Mechanical Properties:

- Slightly lower strength than 410

- Better toughness and reduced cracking risk

Corrosion Resistance:

- Improved resistance to intergranular corrosion

- More stable in mildly acidic or humid conditions

Typical Applications:

- Welded stainless steel pipes

- Heat exchangers

- Light-duty food machinery

430 Stainless Steel – Economical Ferritic Grade

Mechanical Properties:

- Stable strength without heat treatment

- Good ductility and formability

Corrosion Resistance:

- Excellent resistance to atmospheric corrosion

- Inferior to 304 in acidic environments

Typical Applications:

- Refrigerator doors and washing machine drums

- Kitchen appliance panels

- Architectural trim and elevator doors

4. Ganyeah Group’s Chromium Stainless Steel Solutions

Ganyeah Group supplies 410, 410S, and 430 stainless steel pipes, tubes, and components with stable quality and controlled chemical composition. Our products are widely used in mechanical manufacturing, home appliances, construction, and general industrial applications, helping customers achieve the optimal balance between performance and cost.

Our engineering team supports material selection based on real service conditions, ensuring each project uses the most suitable stainless steel grade—not simply the most expensive one.